Cleanroom Data Recovery vs. Clean Benches: A Scientific Perspective

When recovering data from physically damaged hard drives, few topics generate more discussion than the type of environment where recovery work is carried out. For years, DriveSavers has highlighted its cleanroom data recovery capabilities as a technical point of difference. But is a clean bench — a smaller, more affordable controlled environment — good enough? Let’s explore how DriveSavers Data Recovery’s investment in a fully ISO-certified cleanroom stands up under scientific scrutiny.

Let’s take a closer look through a scientific lens.

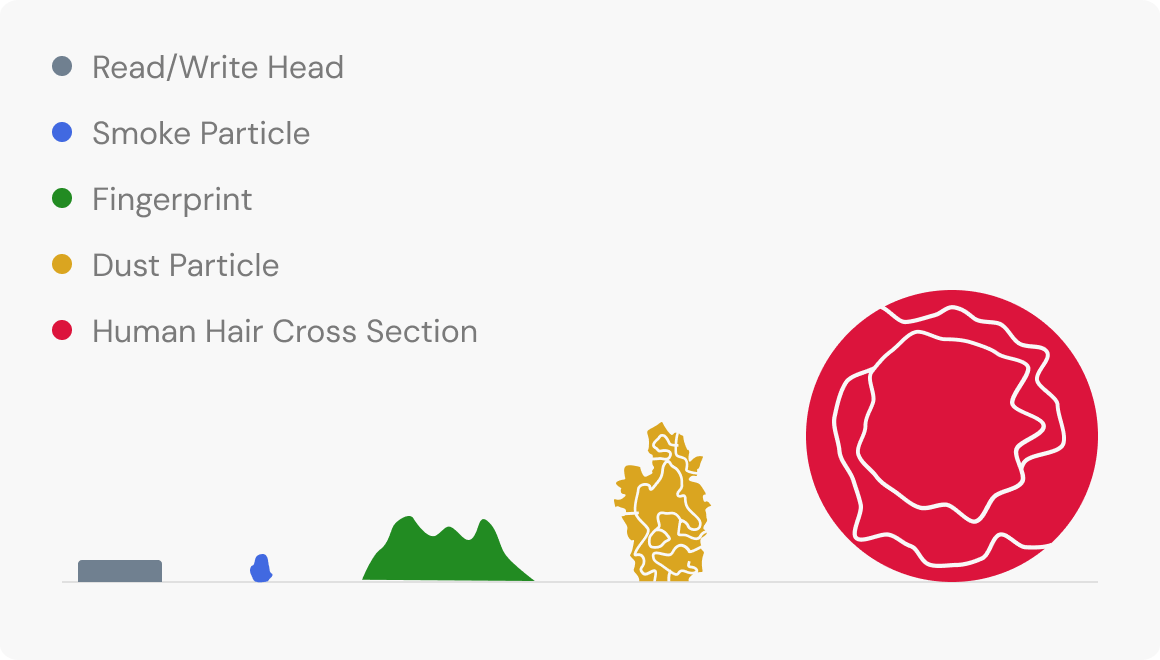

A cleanroom is a purpose-built, enclosed space where airborne particles, humidity and temperature are precisely controlled. Cleanrooms are rated according to standards such as ISO 14644-1, which defines the maximum number of particles permitted per cubic metre. DriveSavers operates at ISO Class 5, allowing fewer than 3,520 particles (0.5 μm or larger) per cubic metre.

A clean bench, on the other hand, is a localized area that uses laminar airflow and HEPA filtration to provide a particle-free work surface. While clean benches can be quite effective for certain applications — like electronics assembly or some lab work — they differ fundamentally in scope:

The key to cleanroom hard drive recovery is preventing contamination of the sensitive internal components — platters, read/write heads, actuators — within data storage devices. Even microscopic dust particles can trigger head crashes, drastically lowering recovery success rates.

Think of it like a racecar slamming into a boulder — that’s the scale of disruption a single dust particle can cause.

While clean benches protect the immediate work surface, they don’t fully eliminate risks from ambient air, technician movement, or ESD. DriveSavers’ cleanroom protocols are specifically designed to mitigate all of these variables.

It’s true that some recoveries can be completed successfully on a clean bench. If the hard drive platters are largely undamaged and mechanical failure is minor, bench-level containment might be enough.

But here’s the challenge: DriveSavers handles a wide range of scenarios — fire-damaged drives, flood-soaked systems, corrupted firmware, degraded magnetic media — where even a single airborne contaminant could make the difference between recovery and total loss.

In such edge cases — where there’s only one shot to get it right — the question shifts from “what’s adequate?” to “what gives the best chance?”

For DriveSavers, operating an ISO-certified data recovery cleanroom is a deliberate strategy to maximise recovery outcomes and minimise the risk of additional damage. These drives often hold more than just data — they contain intellectual property, legal documentation, financial records or irreplaceable family memories.

With so much at stake, DriveSavers chooses to meet the highest environmental standards in the industry — even though 90% of jobs might be recoverable with less.

It’s about reducing the remaining 10% risk — and for many customers, that 10% is everything.

For some professional recovery firms — particularly those handling low-cost or consumer-grade drives — clean benches offer a practical, cost-effective solution. They’re easier to maintain and suitable for less complex cases.

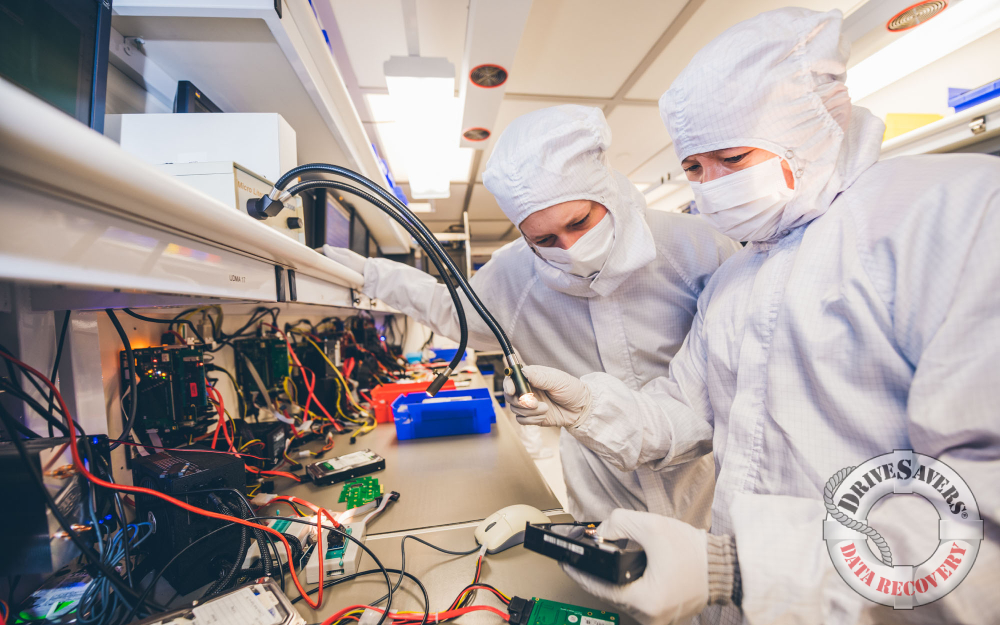

The cleanroom is part of DriveSavers’ broader approach to comprehensive risk control — not just for the workspace, but for every surrounding process.

For routine recoveries, a clean bench may suffice. But data recovery isn’t a one-size-fits-all job. DriveSavers invests in a cleanroom because it gives our engineers the best possible conditions to succeed.

An ISO Class 5 Certified Cleanroom provides science-backed risk reduction.

Expertise, Not Equipment, Wins the Day

DriveSavers’ cleanroom is a key advantage — but it’s not the only one. Successful data recovery also depends on engineering expertise, proprietary tools, and advanced reverse-engineering skills. The cleanroom simply amplifies these strengths.

A clean bench in expert hands may outperform a cleanroom used improperly. But when world-class engineers work inside an ISO-certified cleanroom, you get the highest possible chance of success and data safety.

That’s what DriveSavers delivers: not just a clean place to open a hard drive — but an environment where your data has the best chance to be recovered and protected.